Current location:Home > News > Company news

Selection of weighing sensor

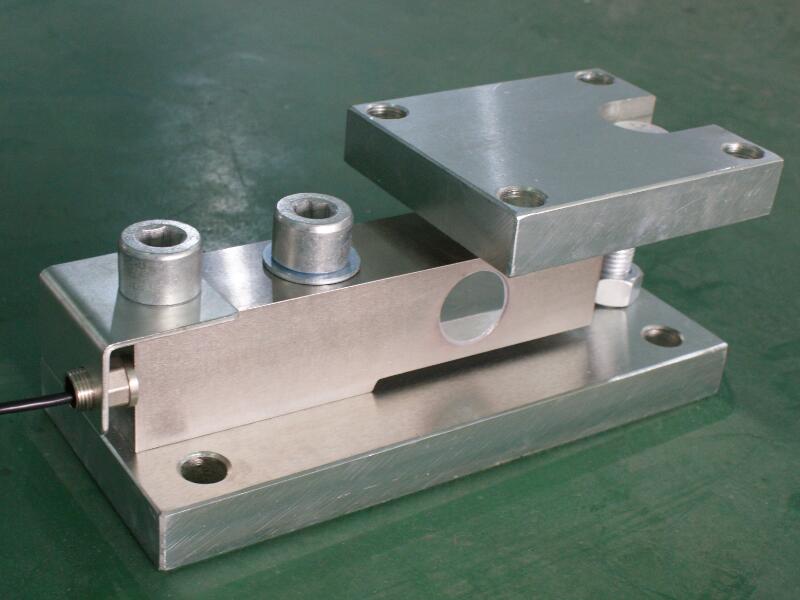

The choice of the form of the load cell depends primarily on the type of weighing and the installation space to ensure proper installation and safe and reliable weighing. On the other hand, the manufacturer's recommendations should be considered. For sensor manufacturers, it generally specifies stress conditions, performance specifications, mounting styles, structural forms, elastomeric materials, and the like. For example, aluminum alloy cantilever sensors are suitable for electronic pricing scales, platform scales, case scales, and the like. Steel cantilever sensors are suitable for electronic belt scales, sorting scales, etc. Steel bridge sensors are suitable for railway scales, truck scales, etc. The column sensor is suitable for truck scales, dynamic rail scales, large tonnage hopper scales, etc.

Application area of load cell

Weighing sensors are mainly used in various electronic scales, industrial control fields, online control, overload alarms, material testing machines, etc., such as electronic vehicle balance, electronic platform scales, electronic forklifts, dynamic axle weight scales, electronic crane scales, electronic evaluation scales. , electronic steel scales, electronic track balance, material scales, filling scales, etc.

A sensor is actually an output device that converts high-quality data signals into data signals that can be accurately measured. The controller must first consider the specific office environment in which the controller is located. In fact, proper use of the controller is especially important. It is related to the normal operation of the controller and other safety and service periods, as well as the reliability and safety factor of the entire electronic scale.

Load cell application environment

In general, high-temperature environments cause problems such as melting of the material to be coated, opening of the solder joint, and structural changes in the internal stress of the elastomer. Dust and moisture can cause short-circuit effects on the sensor and are highly corrosive. In the environment, sensor elastomer damage or short circuit occurs, and the electromagnetic field may interfere with the sensor output.